Process Control Thermostats

Process Control Thermostats

30000 Surface Mount Temperature Controller & SBKT Control Panel Thermostat

The 30000 Surface Mounting Controller operates on the principle of the differential expansion of metals. A temperature increase causes the stainless steel outer case to expand at a greater rate than the internal bridge assembly. Because the case is in direct contact with the heated surface, a temperature change is sensed almost instantaneously. With an increase in temperature, the case expands. This results in a linear change of the internal bridge assembly causing the electrical contacts to open. A decrease in temperature closes the contacts.

CH Infinite Control Mechanism

The CH gives infinite control for noninductive loads up to 15 Amps on 120 or 240 Vac (cannot be used with external contactor). It can be turned either to left or right to select proper heat from 0-100% wattage with infinite control over the first 50% of total wattage.

ARC Non-Indicating Thermal Cutout

When properly applied, the ARC protects against damage due to product or heater overheating by opening a circuit when a preset temperature is reached.

AR-EP Non-Indicating Temperature Controllers

Bulb and Capillary style thermostats use expanding liquid to open or close contacts in response to temperature changes. Simple to use with a calibrated knob for setting the temperature and the ability to directly switch load current for one of two poles directly. Double pole, single throw contacts that open on temperature rise. At positive off position, contacts cannot close.

AR & ARR Non-Indicating Temperature Controllers

Bulb & Capillary Temperature control of any electrically heated solid, liquid or gas. Bulb and Capillary style thermostats use expanding liquid to open or close contacts in response to temperature changes. Simple to use with a calibrated knob for setting the temperature and the ability to directly switch load current for one of two poles directly.

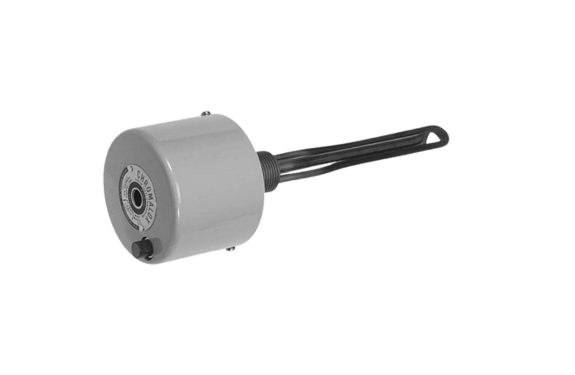

17000 & 18000 Cartridge & Immersion Temperature Controllers

Cartridge type is designed for drilled hole cartridge heating installations in molding presses, platens, rubber vulcanizers, hot plates, etc.

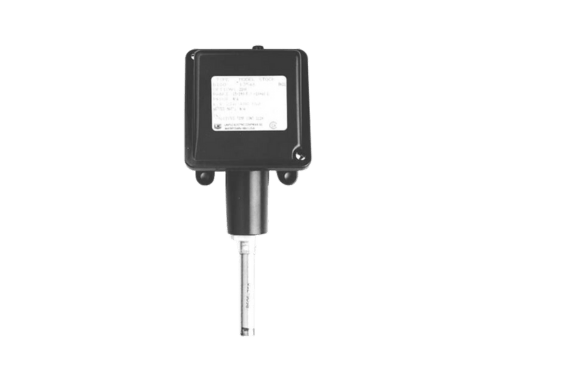

PIT Non-Indicating Temperature Controller

For a variety of process applications requiring a rain-tight, PIT controllers may be used in pipe tracing and snow melting applications with electric heating cable.

BCT Indicating Temperature Controller

Temperature control of any heated or cooled solid, liquid or gas.

• BCT-800 for NEMA I General Purpose Enclosure Applications.

• BCT-820E for NEMA 4, 7 or 9 Explosion Proof Enclosure Applications.

Technical Resources

30000 Surface Mount Temperature Controller & SBKT Control Panel Thermostat

30000 Catalog Page

30000 Surface Mount Temperature Controller

CH Infinite Control Mechanism

CH Installation Manual

CH Infinite Control Mechanism Catalog Page

ARC Non-Indicating Thermal Cutout

ARC Installation Manual

ARC Catalog Page

ARC Non-Indicating Thermal Cutout

AR-EP & AR-LT Non-Indicating Temperature Controllers

AR-EP Installation Manual

AR-EP & AR-LT Catalog Page

AR & ARR Non-Indicating Temperature Controllers

AR (Single Phase) Installation Manual

AR (Three Phase) Installation Manual

AR & ARR Catalog Page

ARR Installation Manual

17000 & 18000 Cartridge & Immersion Temperature Controllers

17000 & 18000 Catalog Page

17000 & 18000 Installation Manual

BCT Indicating Temperature Controller

BCT Catalog Page

BCT Installation Manual

PIT Non-Indicating Temperature Controller

PIT Non-Indicating Temperature Controllers Catalog Page

PIT Installation Manual

Request a Quote

Every heating challenge is unique. Chromalox offers the industry’s most comprehensive offering of component heaters and controls. Our experienced engineers will work with you to provide a complete thermal solution for your unique application.